Coating

Performance, where its needed

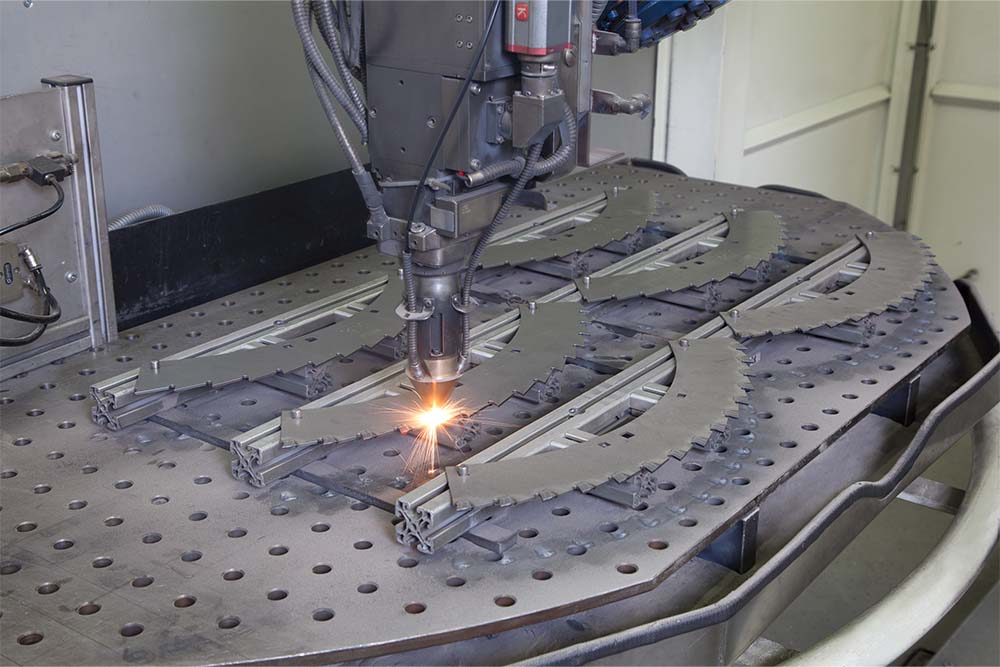

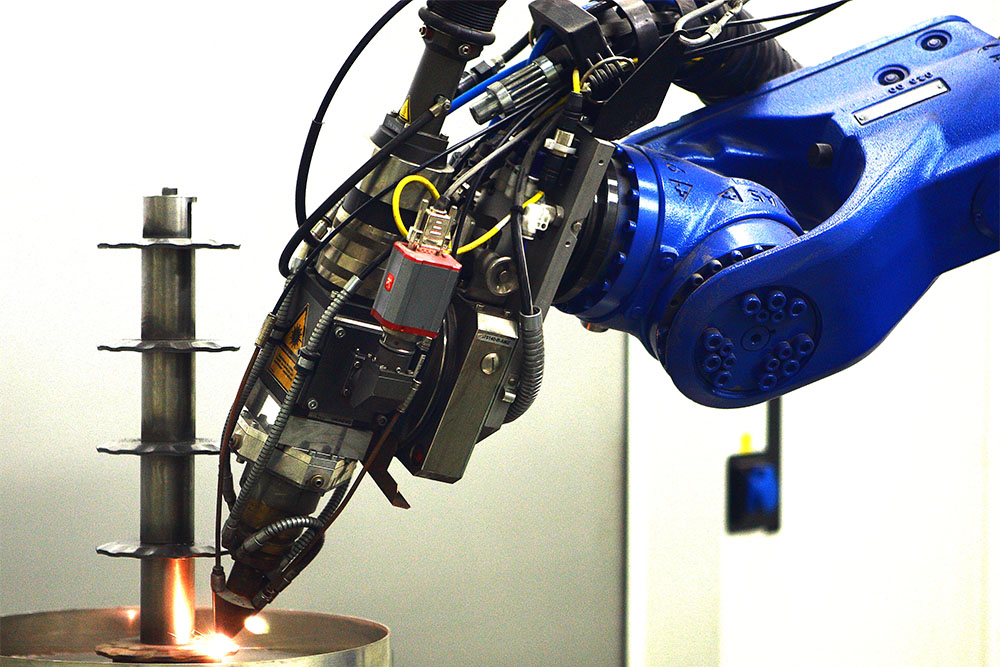

Using high-tech coating processes with wear-resistant materials, our knives are optimized to the maximum for a subsequent use. The complex work steps are carried out by linear systems or robots so that we can ensure and guarantee consistently high quality. Essentially, three proven and established coating processes are used, which we will briefly introduce.