Bainitizing is especially suitable as heat treatment, for components with a high carbon content. The metal will be heated to the required hardening temperature and then, for a certain time, held in a tempered quenching medium. We use a salt solution for this purpose. The process creates a so-called bainitic structure that hardens the steel.

With this process, multi-purpose chamber furnaces or continuous furnaces are being used. The steel components and knives are heated to the required hardening temperature and quenched with oil. This is followed by another tempering process to reduce stresses in the material and to achieve the desired hardness.

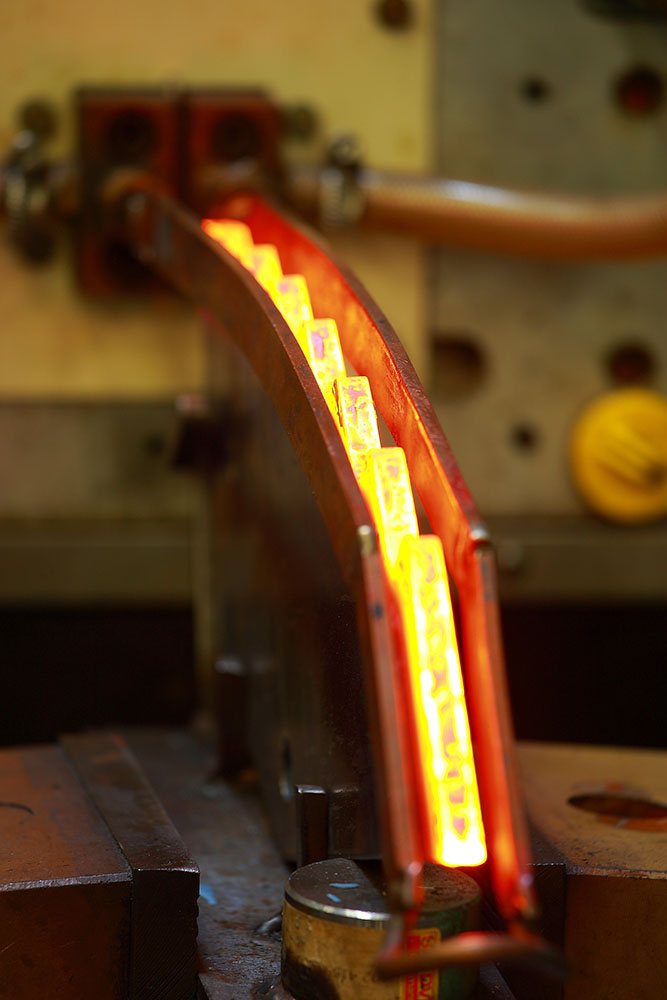

With this process, predefined areas of a component can be partially hardened using induction coils. The tempered components are then quenched in a water solution and subjected to a tempering process, to reduce stresses in the material.

Do you want to learn more about our products and our technology? Do you need information on a specific topic? Or do you have an individual question? Do not hesitate to contact us.

Our decades of experience in the processing of steel and our commitment to service, flexible delivery performance and technical development make us a strategic and reliable partner for our customers in every aspect.