Application area

High performance for your shredding technology

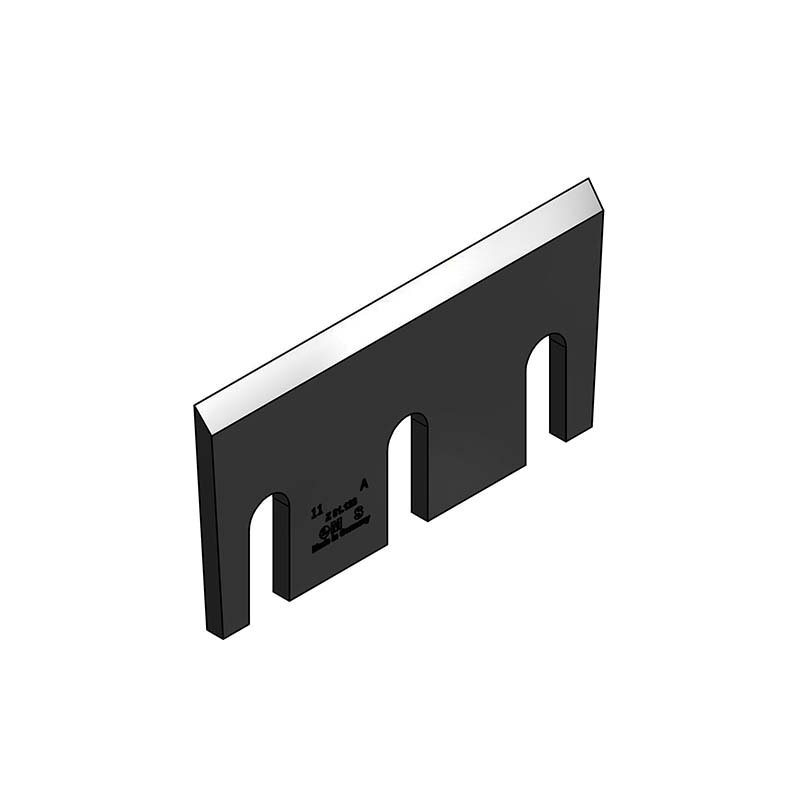

Our customers particularly appreciate our chopper blades because of the long-lasting sharpness of their cutting edges, the high resilience of the steel and the high processing quality. The focus is on the economic efficiency of our shredder blades. The exact cut also has a significant influence on the quality of the shredded material. The blades can be used in the shredder units of forage harvesters made by Claas, John Deere, Krone and Mengele.